Grinding Off Ryzen 7000 IHS Seemingly Lowers Temps By 10 Degrees Celsius

Lower temperatures at the cost of voiding the warranty

AMD has already received much criticism for using a unique design for the integrated heat spreaders (IHS) of its Zen 4 processors. So now enthusiasts are trying to find ways to improve cooling. One of the hacks is to remove the IHS altogether, but a bit less risky method is to reduce the heat spreader's thickness by grinding it down or, in other words, lapping the CPU.

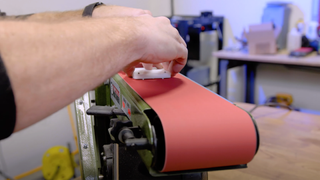

JayzTwoCents (via Andreas Schilling) grinded off the heat spreader of his Ryzen 9 7950X by 0.8mm and reduced the temperature of the processor from around 94 to 95 degrees Celsius to approximately 85 to 88 degrees Celsius at the same 5.10 GHz all-core frequency, depending on the thermal paste used. Furthermore, pushing all cores to 5.40 GHz increases its temperature to 90.65 degrees Celsius. The simple modification requires a special frame from Roman 'der8auer' Hartung, a grinding tool, and a lot of time and sweat, but the reward seems quite promising. Unfortunately, it voids the processor's warranty.

AMD equipped its latest Ryzen 7000-series processors with a very thick (3.6 mm) heat spreader to make them compatible with coolers designed initially for its processors in AM4 form factor. While compatibility means that owners will not have to spend money on new expensive coolers, the thermal conductivity of an IHS that is believed to be over 1 mm thicker than typical heat spreaders also makes it difficult to cool down these CPUs, which means higher temperatures, lower boost clocks as well as inferior overclocking potential. AMD says it is safe for its Ryzen 9 7950X to hit 95 degrees Celsius, but enthusiasts disagree.

Roman 'der8auer' Hartung, a renowned overclocker and engineer, has demonstrated how delidding an AMD Ryzen 9 7900X reduces its temperature by up to 20 degrees Celsius. But delidding is a relatively risky process. Moreover, a delidded CPU requires a modified cooling system mounting mechanism, as CPU coolers are for processors with an IHS.

Making IHS thinner is a whole different story. If done right, it seems less risky, but it requires more time, some skills with a grinding tool, and additional tools to clean the chip up after grinding (and then dry it). Also, it does not necessarily necessitate a heavily modified retention mechanism of the cooler. Of course, one will still need to find the right combination of washers and screws, but it is easier than changing the whole retention mechanism.

Because both delidding and grinding voids warranty and removal of the heat spreader lower temperature by up to 20 degrees Celsius, whereas grinding off 0.8 mm from the IHS drops the temperature by 7 to 10 degrees Celsius, delidding is a preferable mod. Yet, even a thinner heat spreader protects the die from accidental damage, so it all comes down to an individual choice.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Anton Shilov is a Freelance News Writer at Tom’s Hardware US. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

TechieTwo It's technically ignorant to claim that the Ryzen 7000 IHS prevents the CPU from being cooled properly because it's untrue. Grinding the IHS down isn't very smart either unless you like small expensive paperweights.Reply -

InvalidError 1mm of copper with a mean useful heat-conducting cross-section of 3cmsq adds less than 1C per 100W to thermal resistance between the die and HSF. If you get a 10C cooling improvement from grinding 1mm off, something else such as IHS flatness or rigidity must be at play for the 7-8C beyond copper's thermal resistance.Reply -

PlaneInTheSky Please don't copy what this idiot is doing, he's clearly never used a sander.Reply

Not wearing any eye protection while sanding metal with an aggressive belt sander is a great way to end up with a piece of metal in your eyeball.

Also, for the love of god don't blow away the metal slivers you just ground off like he did. You don't want that stuff in your lungs. -

bit_user Has anyone checked how flat the heat spreaders are? One explanation for the improvement is simply improving the thermal interface by eliminating gaps, especially if you do the same thing with your cooler (or the cooler you're using is already really flat).Reply

I've lapped a few heatsinks and a CPU. I didn't bother to take before/after measurements, but others have.

BTW, is it plausible that the height of these heat spreaders has something to do with preparing the platform for CPUs with V-Cache or in-package DRAM (either DDR5X or HBM) stacks? Or are they just waaay too thick for even that to make sense?

My other theory (though it's really more of a fantasy) is that they wanted to use a vapor chamber. I think the ideal scenario would be to somehow make a vapor chamber, the bottom of which is comprised of the PCB/substrate and dies. So, you'd effectively have phase-change direct-die cooling. That would eliminate hotspots on the heatspreader, making it much more effective at conducting heat into whatever you mount atop it. -

Amdlova Lapping give good result and don't need a machine only time and love. My old pentiums and core 2 Duo have little heat when give 70% oc :) nice temps. Today i don't care if The cpu will be at 99°CReply -

Co BIY Replybit_user said:BTW, is it plausible that the height of these heat spreaders has something to do with preparing the platform for CPUs with V-Cache or in-package DRAM (either DDR5X or HBM) stacks? Or are they just waaay too thick for even that to make sense?

I think this makes sense. Room for the 3D stack with a thinner heat spreader reaching the same end height for cooler compatibility. -

escksu Replybit_user said:BTW, is it plausible that the height of these heat spreaders has something to do with preparing the platform for CPUs with V-Cache or in-package DRAM (either DDR5X or HBM) stacks? Or are they just waaay too thick for even that to make sense?

Nope. Thickness of the heatspreader is to prevent warping. Why AMD needs to do that is because of the shape of the heatspreader. Those cutouts at the sides (to cater for the smd caps) greatly reduce the stiffness of the heatspreader, so it has to be much thicker. thicker HS also reduces hot spot.

These are desktop parts so there won't be any HBM. Vcache wise, still unknown. AFAIK, vcache has limited success as only specific applications are able to utilise the additional cache. Focus of vcache is on server parts, not dekstop parts. -

thestryker Reply

There is something going on with the 7xxx IHS as removing it gives an outsized reduction in temps and Der8auer told Jayz that he was seeing 6-7c drops maximum from lapping 1.2mm (the 10c drops in the video also were linked to paste). I hope someone is able to figure out what is going on, but the thermal transfer is clearly bad as it stands if these things are having such a big impact.InvalidError said:1mm of copper with a mean useful heat-conducting cross-section of 3cmsq adds less than 1C per 100W to thermal resistance between the die and HSF. If you get a 10C cooling improvement from grinding 1mm off, something else such as IHS flatness or rigidity must be at play for the 7-8C beyond copper's thermal resistance. -

InvalidError Reply

The official line from AMD is to maintain the same overall IHS height from the motherboard as AM4 for HSF backwards compatibility at least with coolers that use the standard backplate which is now integrated with the AM5 socket latch and cannot be easily swapped out.escksu said:Nope. Thickness of the heatspreader is to prevent warping.

How thick is the indium solder TIM on these things? I could imagine thinning the IHS allowing it to bow in a little with mounting pressure and cause some of the excess solder to ooze out once heat is applied. It wasn't so long ago that Intel got heavily criticized for high temperatures which were ultimately found to be caused by the TIM being 2-3X thicker than absolutely necessary.thestryker said:I hope someone is able to figure out what is going on, but the thermal transfer is clearly bad as it stands if these things are having such a big impact. -

thestryker Reply

Intel had stopped using a soldered TIM for some time which is where a lot of the issues seemed to stem from there. Der8auer didn't mention anything off when he delidded the first 7xxx and I imagine he would have if there had been excess TIM. Nothing from the video seemed to be obvious to my untrained eye as far as appearing to have excess either. This is his original delidding 7xxx video.InvalidError said:How thick is the indium solder TIM on these things? I could imagine thinning the IHS allowing it to bow in a little with mounting pressure and cause some of the excess solder to ooze out once heat is applied. It wasn't so long ago that Intel got heavily criticized for high temperatures which were ultimately found to be caused by the TIM being 2-3X thicker than absolutely necessary.

I don't want to discount flex having a potential impact because I don't really know enough specifics about the designs etc and thinning it would certainly allow for a lot more potential flex. There's definitely something in the design of the IHS directly relating to the thermal transfer performance being bad. Hopefully someone doing an article/video on lapping will do tests along the way to eliminate flatness as a culprit.

Most Popular